- Home

- Products

- Minerals

Minerals

We are bulk supplier of minerals. Our range includes Red Ocher, Dolomite, China Clay, Quick Lime, Hydrated Lime, Limestone, Soap Stone, GGBFS, Slag, Fly Ash and Gypsum,The entire range of mineral are widely used in various industries like steel, cement, tiles, ACC Block, textile, chemical and many more. We offer these products to our clients at very reasonable prices. We have a strong R&D team, aimed at achieving high quality consistency.

Red Ocher :

We have positioned ourselves as one of the most promising bulk supplier of Red Ochre, We offer superior grade of RED OCHER MINERAL. Presentlly we are supplying to Steel Industries / Cement Industries / Paint Industries.

Lime Stone / Quick Lime / Hydrate Lime :

We have firmly positioned ourselves as one of the most promising Suppliers of Limestone based in India. The Limestone provided by us contains silica in different proportions and is largely composed of calcite mineral. Our Limestone finds its application in varied industrial applications. Made available in varied types and grade, the Limestone available with us is surely the right choice to vouch for. The clients can obtain the Limestone at pocket friendly prices from us.

Attributes :

- Excellent quality

- Easy to cut

- Absorbs water

- High solubility

Grades of Limestones Offered By Us As Per Applications

Cement Industry :

Limestone containing about 45% CaO and above is usually preferred for the manufacturing of cement. The proportion of Al2O3 + Fe2O3: SiO2 should be 1:2:5. Magnesia sulphur and phosphorus are regarding as most undesirable impurities.

Iron & Steel Industry :

Limestone is used in this industry both in the blast furnace to lower the temperature of melting and second to from calcium silicate by combining with silica of the iron ore, which comes out as slag. For this purpose good fluxing limestone low in acid constituents such as silica, alumina, sulphur and phosphorus is required. The limestone should be dense, massive, preferably fine grained, compact and non-fretting on burning.

Chemical Industry :

Erably fine grained, compact and non-fretting on burning Chemical Industry : The calcium carbide manufactures generally prefer lime containing 95% CaO (min.), not more than 3% SiO2, not exceed 2%.

Sugar Industry :

In sugar industry lime is used for the clarification of juice form can be beets. Milk of lime 1% in volume of cane juice is added to pre-heated juice. Limestone to be used in sugar industry must be high in active lime (CaO S 80% min.) must be low in iron, alumina and silica, etc.

Glass Industry :

Glass industry required high limestone (CaCO3: 94.5%) combine CaCO3 and MgCO3 should be 97.5%.

Fertilizers Industry :

The latest use of limestone introduced in the country is in the manufacture of calcium ammonium fertilizers, limestone is used only as carrier. For this purpose limestone should contain MgCO3 + CaCO3 85% (min.) SiO2 5% (max.) and acid in-soluble 14% (max.).

Chemical Properties

CaCO3 : 85-97%

CaO : 48-54%+

SiO2 : Below 1% - 2 %

Range

Lumps/ Powder/ Chips

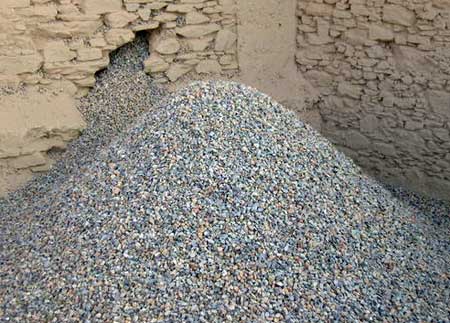

Dolomite :

We are offering a superior quality range of Dolomite to buyers in the domestic as well as international markets. Our Dolomite are widely used in the manufacturing of paints, detergents, plastic compounds etc. Additionally, they are used as filler in the re-processing of the plastic. We are an Exporter and Supplier from Surat (India). We make them available in various mesh sizes and packaging options.

Steel industry uses the dolomite chip & lumps in furnace.

It is a calcium magnesium carbonate with a chemical composition of CaMg(CO3)2

China Clay (KAOLIN):

Kaolin or china clay is a natural mineral found in partly decompo-sed granite, an igneous feldsparic rock. Chemically, kaolin is a hydrated aluminium silicate containing Al2O3.2SiO2.2H2O.

Kaolin was first discovered in the mountainous province of Kiangsi, China in A.D. 500. The word "kaolin" derives from the Chinese character 'kao lin' which means high ridge. It was first used by the Chinese to make high quality porcelain.

At Chandrika Marketing China Clay, is available in white powder form, granule cum powder form, and in lumps form. The various grades and their applications are :

GRADE FORM APPLICATIONS :

- China Clay powder / lumps Paint extenders, filler in paper, ceramic

- Glazing and engobing, Vitrified tiles manufacture

- Ceramic glazing and engobing

- Ceramic body composition

- Powder ceramic glazing

- Powder Pesticide formulation

- Powder Paper

- Powder Paint

- Powder / powder cum granules / lumps Filler in Fiber Glass

Gypsum

Gypsum plaster is among the most commonly used material in the construction and home-remodeling niche. Gypsum is sourced from mineral rocks that contain rich deposits of calcium sulfate. Gypsum plaster is also called plaster of Paris. It is prepared from finely-grounded gypsum, which is heated to extremely high temperatures and then mixed with water. The resulting material, called gypsum plaster, is superior to cement and mortar in many ways.

Fly Ash

Better Performance Without Higher Cost Fly ash – the most commonly used coal combustion product – is a remarkable material that cost-effectively improves the performance of products it is added to.

For instance, in making concrete, cement is mixed with water to create the “glue” that holds strong aggregates together. Fly ash works in tandem with cement in the production of concrete products. Concrete containing fly ash is easier to work with because the tiny, glassy beads create a lubricating effect that causes concrete to flow and pump better, to fill forms more completely, and to do it all using up to 10 percent less water. Because the tiny fly ash particles fill microscopic spaces in the concrete, and because less water is required, concrete using fly ash is denser and more durable. And fly ash reacts chemically with lime that is given off by cement hydration, creating more of the glue that holds concrete together. That makes concrete containing fly ash stronger over time than concrete made only with cement.

Fly ash is a cost-effective resource. When fly ash is added to concrete, the amount of cement that is necessary can be reduced. And finally, fly ash use creates significant benefits for our environment. Fly ash use conserves natural resources and avoids landfill disposal of ash products. By making concrete more durable, life cycle costs of roads and structures are reduced. Furthermore, fly ash use partially displaces production of other concrete ingredients, resulting in significant energy savings and reductions in greenhouse gas emissions.

SLAG

We offer different types of slag, for different usage. Slags are nonmetallic byproducts of many metallurgical operations and consist primarily of calcium, magnesium, and aluminum silicates in various combinations. Iron and steel slags are coproducts of iron and steel manufacturing. In the production of iron, the blast furnace is charged with iron ore, fluxing agents, usually limestone and dolomite, and coke as fuel and the reducing agent. The iron ore is a mixture of iron oxides, silica, and alumina. From this and the added fluxing agents molten slag and iron are formed. The physical characteristics such as density, porosity, and particle size, are affected by the cooling rates and chemical composition. Depending on the cooling method, three types of iron slag are produced— air cooled, expanded, and granulated— that have different types of applications.